Tubular inspection Services

COYAPS intend to serve the oil companies by providing timely, high quality, cost effective Tubular Inspection Services. Tubular Inspection includes inspection of new and used oil tubular goods covering: Drill Pipes, Heavy Weight Drill Pipes, Drill Collars, Casing, Tubing and Bottom Hole Assembly.

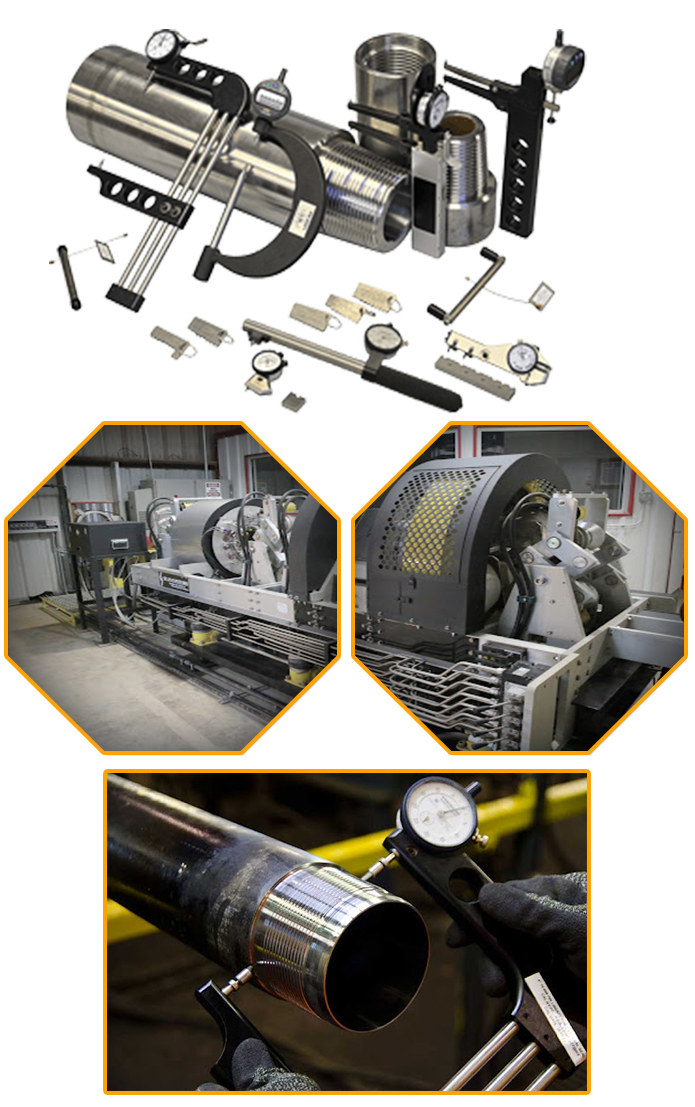

Coyaps Cover All Tubular Inspection :-

• Electromagnetic inspection unit – EMI for Drill Pipe Body Inspection

• Electromagnetic inspection unit – EMI for Tubing Body Inspection

• Electromagnetic inspection unit – EMI for Casing Body Inspection

• Magnetic particle inspection – MPI

• Ultrasonic Share Wave

• Ultrasonic Thickness Gauges

• Thread Gauging Unit

• Straightening Machine

• Internally Full Length Cleaning Machine

• Externally Full Length Cleaning Machine

• Break Out Bucking Machine

• Visual Pipe Inspection

• Dimensional Inspection of Pipe

• Visual Thread Inspection

• Tool Joint Dimensional Inspection

• Dimensional Inspection of Rotary Shoulder

• Wet fluorescent magnetic particle (black light) inspection

• Dye Penetrant Testing API Full Length Drifting

• Hardness Testing

At COYAPS – All engineers are trained to the highest standard through both internal and external training and undergo regular competency assessment to ensure they are up date with all the relevant procedures and standards.